| |

|

|

| Our composite

hoses are designed to ensure the highest

levels of reliability, durability and

safety but, to maintain these levels,

regular inspection, cleaning and testing

are essential. |

|

|

Worn or

damaged hoses may be dangerous, so they

should be visually checked before each

operation and given a more rigorous

examination at least every six months.

The inspection should pay attention to:

1- Dents or kinks.

2- Displacement of inner and outer

reinforcing wires from their normal

pitch.

3- Corrosion or abrasion of the outer

wire.

4- Displacement of end fittings or signs

of leakage from the ends.

5- Other abnormal features including

wear or damage to end fittings.

6- Chemical attack. Deterioration or

physical damage to outer cover and

carcass generally.

Hoses with any significant defects of

the above type should be retired from

service. Moderate abrasion of the outer

cover is acceptable if the reinforcing

fabrics below the cover are undamaged. |

|

|

Hoses should

be cleaned after use and always before

testing or prolonged storage . The most

appropriate method will depend on the

hose use and its location.

Flushing out is often sufficient with

fluids such as clean water , hot water ,

detergents, common solvents at ambient

temperatures and sea-water. if sea-water

is used, it must be thoroughly drained

afterwards to minimize risk of corrosion

on carbon steel end fitting or

galvanized steel internal wires.

It is essential that any strong acid

convey ants are thoroughly drained prior

to cleaning, to avoid exothermic

creation. It is also important to fully

drain the hose afterwards to ensure

puddles of cleaning fluid are not left

within the assembly. This avoids any

possibility of chemical reaction when

the hose re-enters service.

Lose steam may be used but the hose must

be open-ended and its maximum working

temperature must not exceeded, since

damage to the fabric or film may occur.

Compressed air may be used, but again

the hose must be open-ended.

During cleaning the hose must be

electrically earthed it avoid static

charge build-up especially near

flammable areas. Pigging must not be

used under any circumstances. |

|

|

At least

annually, hose should be hydraulically

tested as follows.

1- Drain and thoroughly clean hose and

check end-to-end electrical continuity.

2- Inspect visually. Hoses failing

visual inspection should not be tested.

3- Lay hose straight out on supports or

roller bed that allows free movement

under pressure.

4- Blank off ends and fill the hose

completely with water. Ensure trapped

air is released by tilting slightly.

5- Pressurize the assembly to 1.5 times

the maximum rated working pressure for

10 minutes while examining for leaks.

Also test electrical between ends to

ensure that it is the same as initially

checked.

6- Release pressure and drain hose.

7- On completion of the test, the hose

should again be tested for electrical

continuity.

It should be noted that with

thermoplastic composite hose, elongation

under pressure can be high relative to

rubber. This is a feature of composite

hoses and unlike rubber hoses. It cannot

be taken as an indication of failure or

used to assess the condition of the hose

reinforcements. |

|

ELECTRICAL

CONTINUITY TESTS |

|

|

To prevent the

accumulation of static charge generated

in use, all metal parts of the assembly

have been electrically bonded during

manufacture. At intervals not exceeding

six months, the following test should be

carried out.

1- Lay hose flat on the ground.

2- Check that it is electrically

continuous end-to-end with a simple

battery and bulb test or an ohm meter.

Hose not having electrically continuity

should be retired from service. |

|

|

To prevent the

accumulation of static charge generated

in use, all metal parts of the assembly

have been electrically bonded during

manufacture. At intervals not exceeding

six months, the following test should be

carried out.

1- Lay hose flat on the ground.

2- Check that it is electrically

continuous end-to-end with a simple

battery and bulb test or an ohm meter.

Hose not having electrically continuity

should be retired from service. |

|

|

| Our composite

hoses are noted for their durability but

their life can be determined by how they

are used in operation. To ensure maximum

service life, follow these simple

guidelines. |

|

|

|

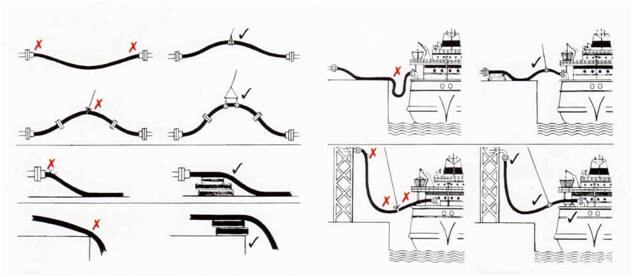

1- Support

hose at appropriate points with slings.

2- Support hose near manifold

connections.

3- Support hose against sharp edges such

as jetty edges and a ship’s guard rill.

4- Store hose in a straight line raised

off the ground, preferably in a cool,

dark area. |

|

|

1- Use hose

unsupported.

2- Support hose with a single rope.

3- Allow hose to drop between ship and

jetty.

4- Over bend hose. |